Products Description

HAFE Water Blocking Airbags: The Ultimate Solution for Pipe Sealing and Leak Prevention

Introduction to HAFE Water Blocking Airbags

When it comes to temporary pipe sealing and leak prevention, HAFE Water Blocking Airbags stand out as a reliable, efficient, and cost-effective solution. These inflatable rubber airbags are designed to create a watertight seal in pipelines, making them indispensable for maintenance, testing, and emergency repairs across various industries.

Engineered with high-strength, corrosion-resistant rubber, HAFE airbags provide a non-destructive sealing method that eliminates the need for welding or permanent modifications. Whether you're working on municipal sewage systems, construction sites, or flood control projects, these airbags offer unmatched versatility and performance.

Key Benefits of HAFE Water Blocking Airbags

1. Superior Sealing Performance

Tight Fit: The airbag expands to conform to the pipe's inner walls, ensuring a leak-proof seal even under pressure.

High-Pressure Resistance: Rated up to 0.1 MPa, these airbags can withstand significant water pressure without failure.

2. Quick and Easy Installation

No Special Tools Required: Simply insert, inflate, and secure—reducing downtime in critical operations.

Reusable Design: Deflate, clean, and reuse multiple times, making them a cost-effective long-term solution.

3. Wide Range of Applications

Municipal & Industrial Use: Ideal for sewer maintenance, pipeline testing, and water diversion.

Construction & Emergency Repairs: Perfect for flood control, bridge construction, and underground pipe repairs.

Pressure Testing: Ensures pipeline integrity before commissioning.

4. Safety & Durability

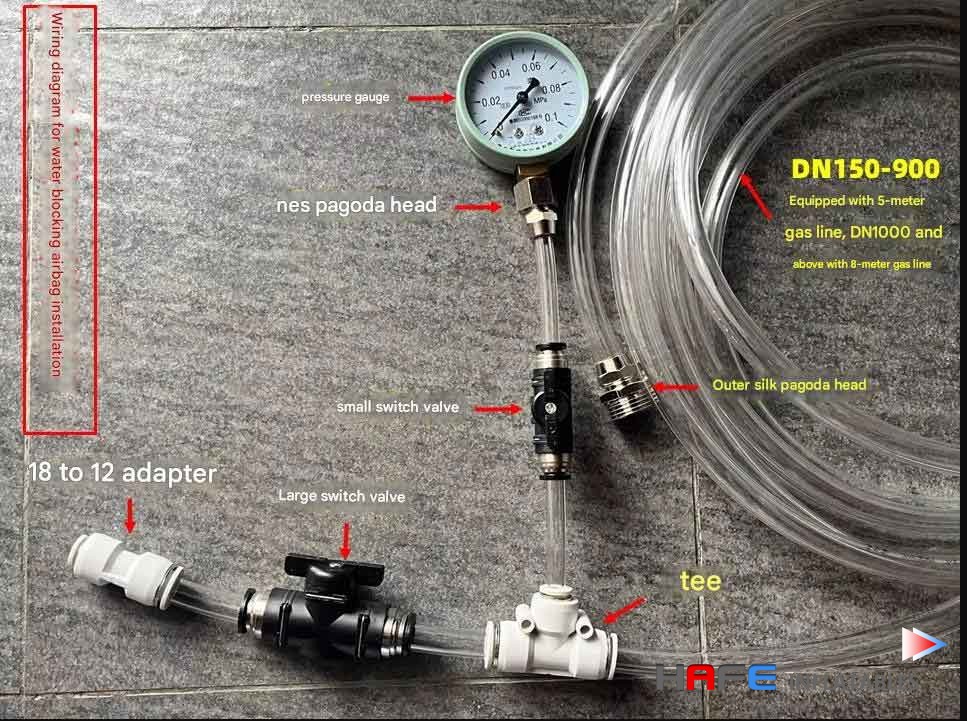

Built-in Safety Features: Includes one-way valves, pressure gauges, and safety release mechanisms to prevent over-inflation.

Rugged Construction: Made from tear-resistant rubber for long-lasting performance in harsh conditions.

Technical Specifications of HAFE Water Blocking Airbags

| Pipe Diameter (DN) | Length (M) | Weight (KG) | Max. Pressure (MPa) |

|---|---|---|---|

| 150mm | 0.60 | 1.8 | 0.10 |

| 300mm | 1.00 | 3.3 | 0.08 |

| 600mm | 1.00 | 5.8 | 0.06 |

| 1000mm | 1.50 | 15.5 | 0.03 |

| 1500mm | 2.25 | 31.0 | 0.02 |

| 2000mm | 3.00 | 54.0 | 0.015 |

| 2400mm | 3.60 | 74.0 | 0.01 |

Best Practices for Using HAFE Water Blocking Airbags

| Step | Guideline |

|---|---|

| 1. Correct Selection | Choose an airbag slightly larger than the pipe diameter for a secure fit. |

| 2. Pipe Inspection | Check for sharp edges or debris that could damage the airbag before insertion. |

| 3. Lubrication | Apply water or non-oil-based lubricant for smooth installation. |

| 4. Slow Inflation | Inflate gradually to avoid sudden pressure spikes. |

| 5. Pressure Monitoring | Use a pressure gauge to ensure safe operating levels. |

| 6. Secure Fixing | Use ropes or metal plates for additional stability in vertical pipes. |

| 7. Regular Checks | Monitor pressure and inspect for leaks during prolonged use. |

| 8. Proper Deflation | Release air slowly before removal to prevent damage. |

| 9. Maintenance | Clean and store in a cool, dry place after use. |

Conclusion

HAFE Water Blocking Airbags provide an efficient, safe, and reusable solution for pipeline sealing across multiple industries. Their high-pressure resistance, easy installation, and durability make them the top choice for professionals in construction, municipal engineering, and emergency response.

For a reliable, non-destructive sealing method, HAFE Water Blocking Airbags deliver unmatched performance and value. Whether you're conducting maintenance, testing, or emergency repairs, these airbags ensure quick, leak-proof results every time.

For more information and to request a quote, visit our contact page or reach out to us directly at [email protected].

OUR ADVANTAGE

18 YEARS EXPORT

18 YEARS EXPORT QUALITY CERTIFICATES

QUALITY CERTIFICATES OEM/ODM SUPPORT

OEM/ODM SUPPORT